Operational Excellence

Demonstrating our commitment to sustainability by embedding it throughout all areas of our operations.

S&C recognizes the ways the power and energy industries can significantly contribute to protecting our planet and reducing the impacts of climate change. We are driven by our guiding principle of Responsible Stewardship and are sensitive to the environmental effects of our business activities. Our approach to decarbonizing operations, diverting our waste impact, and responsibly managing the use of natural resources to enhance circularity is outlined in our Environmental Policy Statement.

Climate Change and Decarbonization

Since beginning our decarbonization journey in 2014, we have made steady progress, reducing our absolute Scopes 1 and 2 emissions by 75 percent and 37 percent, respectively.

In 2023, we took meaningful steps to advance our decarbonization strategy, including formalizing our decarbonization goals. With an ultimate goal of achieving net zero emissions by 2050, our strategy includes developing more sustainable alternatives for some of our switching products that rely on sulfur hexafluoride (SF6) gas, increasing our energy efficiency, reducing use of natural gas, investing in renewable energy generation, and evaluating our supply chain emissions.

We referenced the Science Based Targets initiative best practices in setting our targets, choosing a 2014 baseline in accordance with our first emissions inventory. We also used the United Nations Sustainable Development Goals (UN SDGs) framework to develop our strategy and are pursuing activities associated with the Scopes 1, 2, and 3 emissions reductions.

Global GHG Emissions

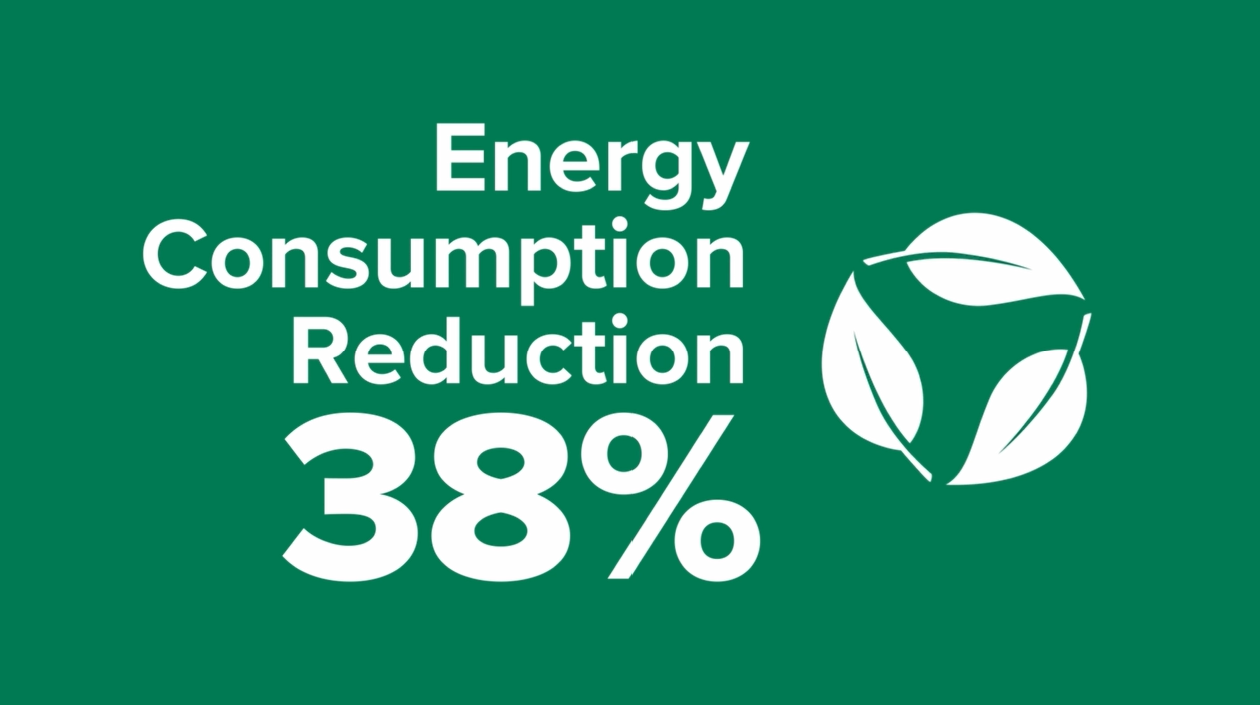

Energy Efficiency

We invest in renewable energy certificates and capital improvement projects, including LED lighting, green building practices, equipment upgrades, and EV charging stations, to continuously improve the energy efficiency of our operations. As the world becomes more reliant on electricity and shifts to using more renewable sources, we are assessing new efficiency programs, including renewable energy generation, electrification of our owned and leased vehicle fleets, and installation of additional EV charging stations at our global locations to further reduce our energy consumption.

Global Electricity Use

Global Electricity Usage Intensity

Waste Management and Diversion

Our global waste management program focuses on prevention, reuse, recycling, and composting initiatives throughout our facilities. Within the last few years, S&C has matured this program by implementing additional material-management and waste-handling practices, including:

- Measuring our waste impact by tracking the amount of waste we generate, reuse, recycle, compost, and convert into energy

- Working with third-party experts to find new ways to decrease waste generation and enhance our waste-handling/disposal processes

- Involving team members in waste-minimization efforts by assembling teams of volunteers

- Reinforcing positive and proactive behaviors aimed at eliminating waste by following the Waste Hierarchy

Global Waste Diverted from Landfills

2023 Global Waste Disposal

Air Quality

S&C has made numerous facility upgrades to reduce the intensity and impact of our activities on air quality, even as our operations have grown significantly. Key initiatives include investing in new powder paint coatings with low to zero volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) in our global manufacturing locations, resulting in a reduction of more than 95% since the 1990s.

VOCs Emissions (U.S.)

HAPs Emissions (U.S.)

Water Conservation

We leverage our lean manufacturing practices, facility upgrades, shared best practices, and conservation efforts to reduce our water consumption. Since 2012, S&C has applied the water conservation lessons learned from efforts at our Chicago headquarters across our global locations.

Global Water Use

Global Water Usage Intensity

Supply-Chain Management

As a global provider of equipment and services for electric power systems, we understand the critical nature of maintaining a resilient, reliable, and responsible supply chain. S&C strives to work with goods and services suppliers that share our values and commitments to quality, dependability, integrity, and mutually beneficial results.

In addition, we:

- Uphold a Supplier Code of Conduct that is accessible on our website and included with all contracts

- Rely on a variety of practices to maintain a sustainable supply chain, including sourcing locally, promoting efficient materials use, and mapping efficient routes

- Strive to build and sustain partnerships with trusted suppliers from a diverse range of backgrounds, including minority- and woman-owned businesses, as well as local and small businesses in the communities where we operate